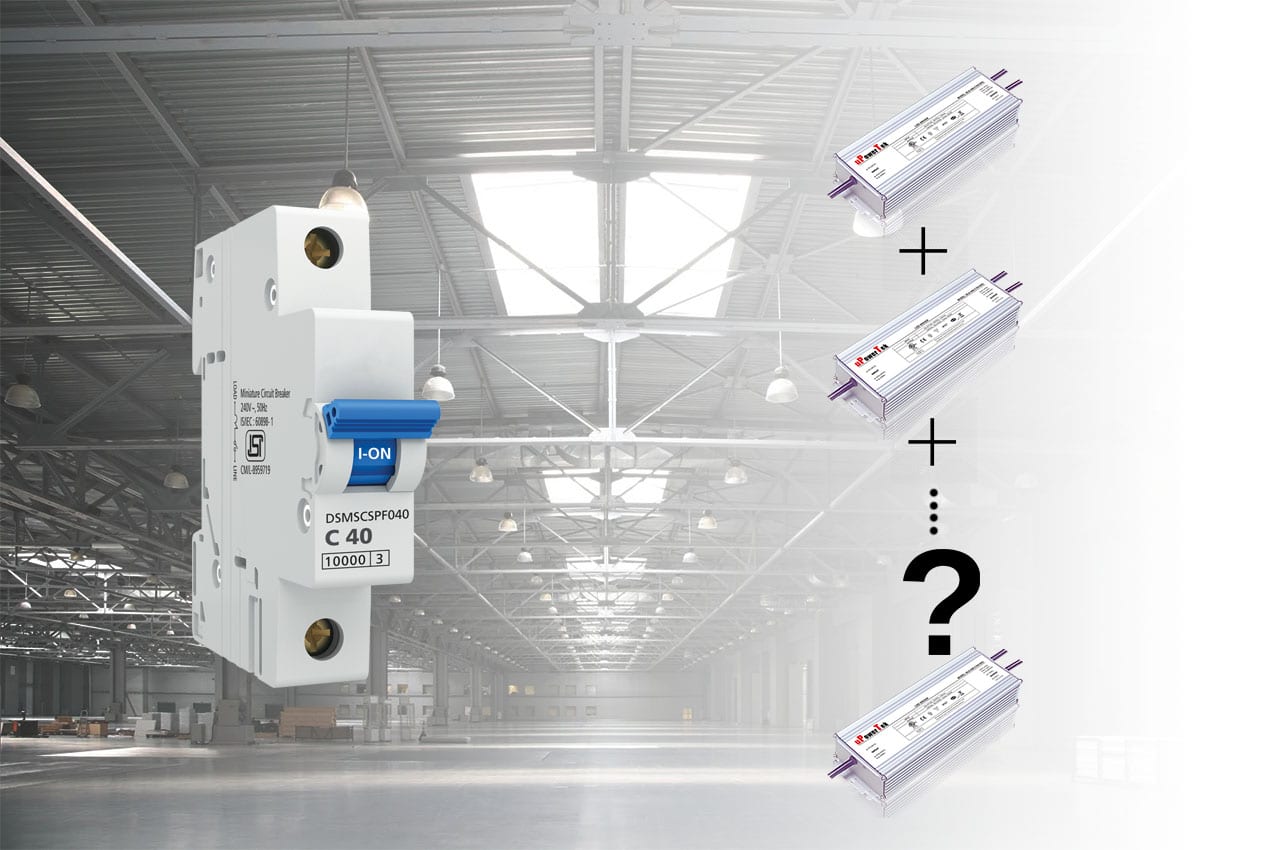

Inrush current in LED light is one area that continues to be a concern in LED lighting. However, the truth is, inrush current does occur not only in LEDs but also in the entire power supply concept. It’s common that an MCB is triggered. So now, let’s see what inrush current and MCB means, and how to calculate the number of power supplies that can be connected to an MCB.

LED Inrush Current Calculator

If you only want to know the LED driver quantity connected to a MCB, you can use the form we designed for you, just simply type the inrush current, pulse duration and input current, then choose the MCB type and you will get the result.

Please keep reading if you would like to know how the number is got.

What is LED Driver Inrush Current

The LED driver Inrush current is the maximum instantaneous input current(Short-duration) flowing into the LED driver at power supply turn-on.

Inrush current goes by other names such as switch-on surge and input surge current. It’s no news that LED drivers experiences high inrush currents that goes up to 100 times the rated continuous current.

Download PDF File

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the e-book immediately.

What Causes Inrush Current in LED Drivers?

Inrush current occurs in any device that draws alternating current from the power source, such as transformer, electric motors, LED drivers, etc.

LED drivers have capacitors that produce a minimal charge on a standard scale with a power supply. As a result, the LED drivers require a high initial current to charge the capacitor, leading to an inrush current. In addition, the time it takes for the input current to charge the capacitor is very fast, creating a switch-on surge.

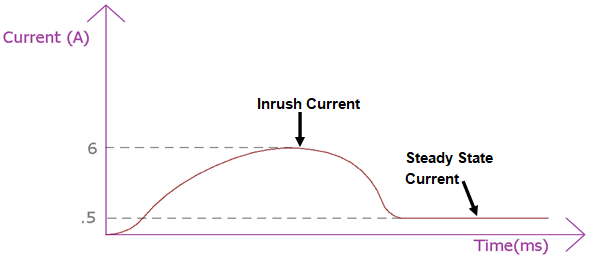

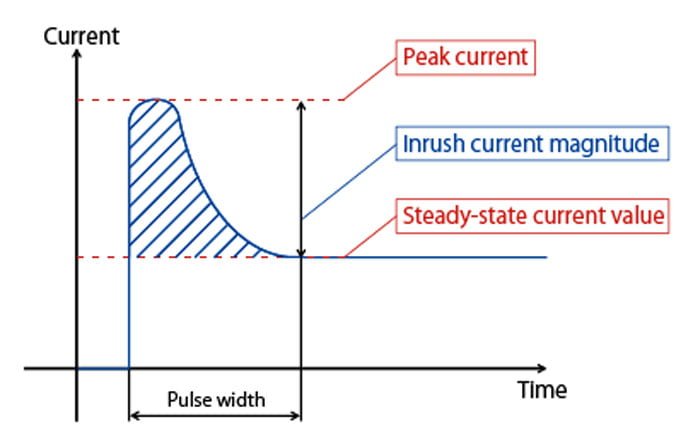

Let’s have a clearer view using the current-time graph below.m the graph,

we see that it takes a few milliseconds for the input current to attain a steady-state. But due to the charging speed of the capacitor by the input current, the current increases to a peak current(denoted by 6A). Then, after a while, the current drops to the steady current(denoted by 5A). Thus, the current that exists at the short time difference is inrush current.

Significance and Identification of Inrush Current

The question which could be running through your minds could be; why are we talking about inrush currents? Or why is it such a concern in the lighting industry? So, to provide answers, we want to see the significance of inrush currents in LED drivers.

The effects of inrush current on LED drivers are not appealing. Track records have it that inrush currents are more of a nuisance than an ally to the LED system. Since the inrush current ratio to that of the steady current is high, it results in a surge that causes the following;

- Tripping of the power switch

- Blown fuses

- Damage to the circuit breaker

- Failure of light dimming system

- Welding relay contacts

In all, inrush current poses a great danger to LED drivers as it can damage the driver and reduce efficiency.

The next task for this section is to help you identify an inrush current. We can achieve this feat by outlining the characteristics of the inrush currents.

- They are instantaneous: occur at the time the LED driver receives power supply

- Posses higher current than the rated current of the driver

- Typically have a voltage range of 120V-240V

- Last for a short time, but effective enough to cause damage

- It averages during a half cycle

How to Calculate Inrush Current?

When calculating the inrush current, you should consider factors like time(duration), peak current, and waveform shape. First, let’s recall the inrush current phenomena which we represent on a graph. You will see that when the LED driver is powered, the input current spikes to a peak current before returning to the steady-state current.

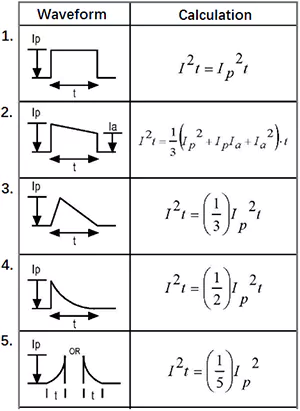

The mechanism above gives rise to a waveform whose shape depends on the varying inrush current level. From these waveforms, we can now calculate the inrush currents. Each shape of the waveform has a suitable formula to calculate the inrush current.

Let’s see the table below:

Where;

Ip = Peak current

Ia = Steady current

t = Time

Alternatively, you can measure the inrush current with devices such as the digital multimeter, clamp meter, and power quality analyzer.

Factors That Influence Inrush Currents of LED Drivers

The factors that influence inrush current include input voltage, temperature, and load. Let’s see how they react with inrush currents

- Input voltage: Inrush currents increases as input voltage also increase.

- Internal Bulk Capacitor: This is the key reason why high inrush current occurs. The higher capacitance, the higher inrush current value.

- Temperature: when there is a high temperature, resistance becomes low, leading to more inrush current. The reverse is the case at a lower temperature of the system.

How to Limit Inrush Current in LED Drivers

Following through this piece, we see that inrush current is a valid fact and poses a great danger to the LED drivers. Therefore, the best step is to explore ways to limit the inrush currents to preserve and improve the LED drivers.

But before we look at the limiting methods, we should understand the factors that help determine the appropriate limiting method.

- Switching time: When there is a rapid switching time, using the negative temperature coefficient (NTC) method becomes unsuitable. The technique is not suitable because there is no time for the NTC to cool down, which will push up the temperature and, in turn, push up the inrush current.

- Load capacitance: A system with high capacitance will need a high transitory current when power is on. As a result, a soft start circuit is ideal to limit the inrush current.

- Low voltage low current phenomena: happen when the load and power source are present in the same circuit. The ideal approach is the use of a voltage regulator.

- Rating of steady-state current: the NTC approach is suitable in this case because a high steady-state current tends to increase temperature.

Done and dusted with the factors, it’s now time we look into the proper limiting methods.

The Negative Temperature Coefficient(NTC) Method

The NTC approach also goes by the name thermistor. It uses the principle of changing resistance at different temperatures. That is, it provides high resistance at low temperatures and low resistance at high temperatures.

The NTC and the inputs are in series; hence when there is a power supply, the NTC gives high resistance, decreasing inrush current.

Soft Start Circuit

It also goes by the name delay circuit, which is mainly present in voltage regulators. The circuit supports the change of output rise time, which in turn decreases the output current. In addition, a soft start circuit helps reduce inrush current.

Miniature Circuit Breakers(MCBs)

A miniature circuit breaker is an electromagnetic device that carries a complete moulded insulating material. The primary function of this device is to switch the circuit. It means to automatically open the circuit (which connects to current) when the current passing through the circuit goes beyond a set value or limit. MCB is designed to protect the cable downstream of the device against overloads and short circuits, preventing damage to cables and equipment. The device can be manually switched ON or OFF, just like standard switches whenever necessary.

Miniature circuit breakers are triggered due to the limitations of the NTC or thermistor in a case where they cannot limit the inrush current. The principle of MCB is, it trips open once it detects a short circuit scenario of overload. Thus, the MCB acts as a barrier as it trips before excess energy flows into the drivers yet still maintains the light.

Types of MCB

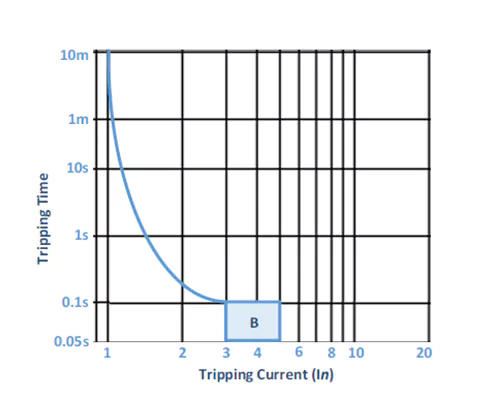

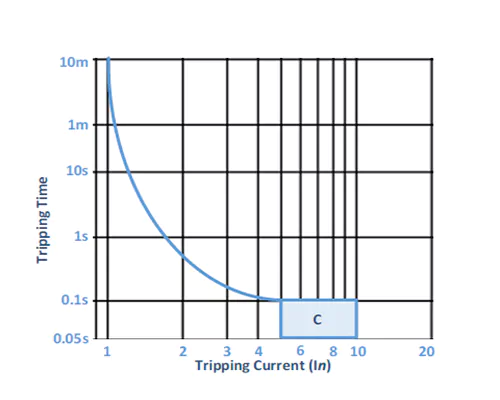

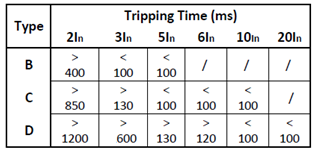

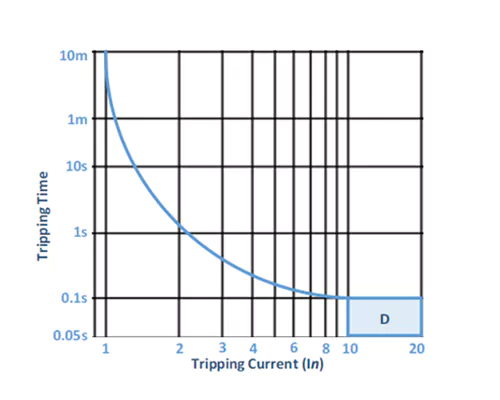

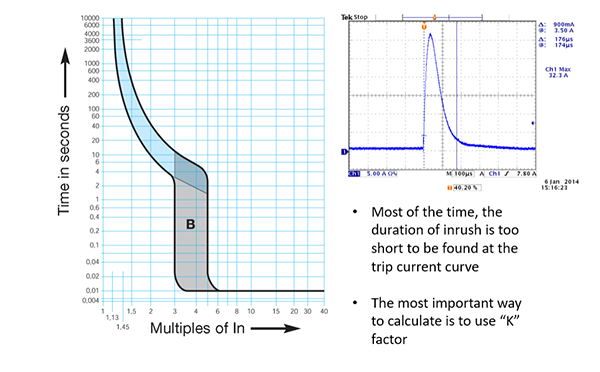

There are 3 MCB types, Type B, Type C, and Type D, and the speed at which they trip depends upon the level of overload and is usually determined by a thermal device within the MCB. A typical MCB tripping curve shows the amount of time required for a circuit breaker to trip at a given overcurrent level as below.

These curves differ from manufacturer to manufacturer and from type to type. Typically, the B type MCB curve has the operating range of 3 to 5 In, C type has 5 to 10In, and D type has 10-14 In according to the datasheets of the most commonly used ABB S201M series.

Tripping Characteristics of MCBs

MCB works by tripping when a circuit is overloaded or when a short circuit has occurred in the system and has a current rating such as 6A or 10A depending upon its intended use, i.e., for residential, commercial, industrial or public buildings. The MCB is tripped in two conditions, steady-state current and instantaneous current also called inrush current.

The ability of the MCB to trip is dependent on the duration of the current and its magnitude. Let’s see a plot that shows the characteristics of each MCB.

The blue curve is the rated current at a given duration from the figures above, and the box area indicates the instantaneous tripping area.

Hence we can summarize the tripping characteristics using the table below.

It shows that a type C MCB can withstand twice the rated current at a duration of 850ms without tripping and three times the rated current for 130ms without tripping.

Want to read it later?

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the e-book immediately.

Formula to Calculate the MCB Rating Needed for the System

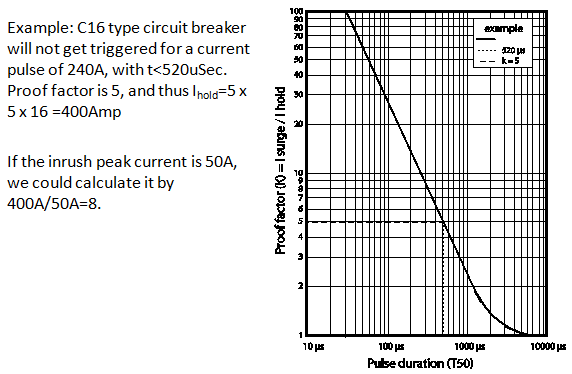

To know the number of LED drivers you can connect in parallel to a single MCB, you will need the image below. The formula to calculate the LED driver load number is Min(Itrip /Idriver ,Ihold/Iinrush). The value is the minimum between two values.

Itrip: MCB rated current (depends on different types of MCB).

Idriver: the maximum input average current of an LED driver.

Ihold: the instantaneous rated current of the MCB.

Iinrush: the maximum inrush current of an LED driver.

And the most critical curve to calculate how many pieces of LED drivers you could parallel is the one below. We need to find the proof factor vs. pulse duration curve from MCB datasheet, then find the impulse duration from the LED driver datasheet, then you can get the proof factor-K value according to the curve. Get the inrush peak current from LED driver datasheet. There are two kinds of duration in the datasheet usually, T50 and T10. T50 means the duration between 50%peak to 50% peak, T10 means the duration between 10%peak to 10% peak. We use T50 data for the calculation.

A typical example to calculate MCB loads is presented below.

Till now, you have learned what is inrush current and how to calculate the number of LED drivers that can be connected to an MCB. If you still have any doubts, you can send us a message to learn more.

uPowerTek LED Driver MCB Selection

First, find the Peak Current-duration table from the MCB datasheet, you can take Apeak as Ihold which we mentioned above.

| Duration [us] | Current B10 [Apeak] | Current B13 [Apeak] | Current B16 [Apeak] | Current B20 [Apeak] |

|---|---|---|---|---|

| 100 | 700 | 910 | 1120 | 1400 |

| 200 | 260 | 338 | 416 | 520 |

| 300 | 177 | 230.1 | 283 | 354 |

| 400 | 145 | 188.5 | 232 | 290 |

| 500 | 122 | 158.6 | 195 | 244 |

| 600 | 110 | 143 | 176 | 220 |

| 700 | 102 | 132.6 | 163 | 204 |

| 800 | 97 | 126.1 | 155 | 194 |

| 900 | 93 | 120.9 | 149 | 186 |

| 1000 | 90 | 117 | 144 | 180 |

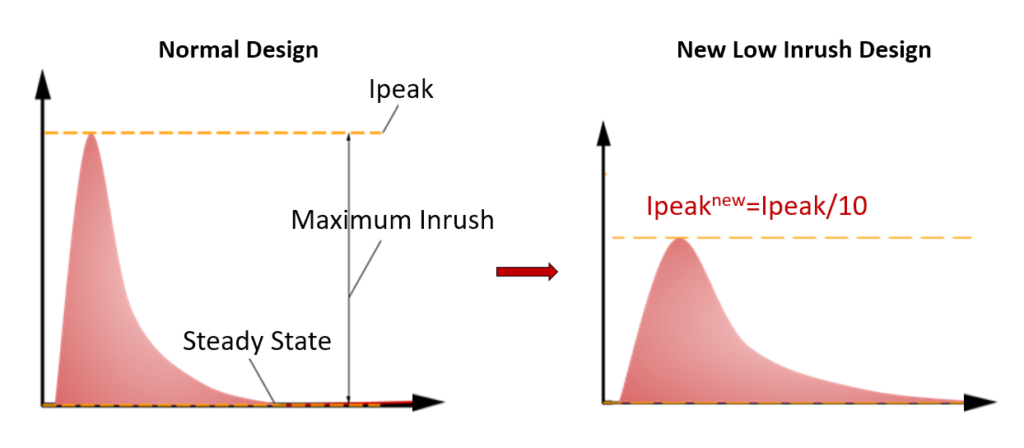

Your best choice of MCB is one that reduces the peak current and pulse duration. Hence, uPowerTek came up with a solution designed to reduce the inrush current in LED drivers.

Ultimately eliminate the MCB Selection Difficulty

When the system becomes bigger, it becomes much more difficult to choose the right MCB. Thus reducing the LED driver inrush current to a certain level which makes the selection calculation only related to the normal operation input current. uPowerTek new LED driver design reduces the inrush current peak value to 1/10 of competitors thus greatly increase the satety of MCB selection.

Final Words

Inrush current is unarguably a threat to LED drivers. We all want efficient LED drivers and even a longer life span for our LED drivers. The good news is, uPowerTek factors in all these problems and designs LED drivers with systems that limit inrush currents. It’s been a remarkable journey as we now have good knowledge of the concept of inrush current. And don’t forget that uPowerTek continues to provide useful knowledge as well as outstanding LED driver solutions.

Contact us now to enquiry the low inrush current LED Drivers!