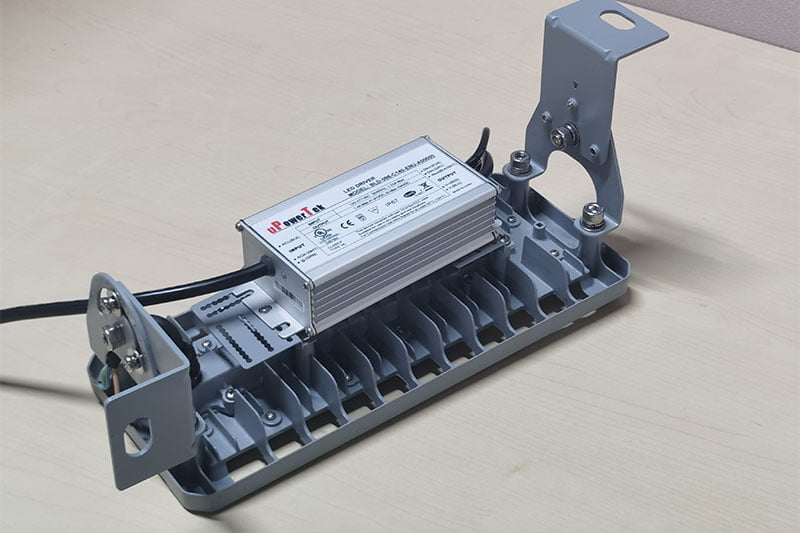

LED drivers are an essential component of LED lighting systems. They convert incoming power to a suitable voltage and current that can be used to power the LED chips. Insulation testing is a critical step in the design and manufacturing of LED drivers to ensure their safety and reliability. In this article, we will discuss the importance of insulation testing for LED drivers and the various methods used for the same.

Why is Insulation Testing Important for LED Drivers?

Insulation testing is important for LED drivers for several reasons:

Safety: Insulation testing ensures that there are no electrical leaks in the LED driver, which could result in a dangerous electrical shock to users.

Compliance: Many countries have specific regulations on the insulation resistance requirements of electronic equipment. Insulation testing ensures that LED drivers meet these requirements and are compliant with relevant safety standards.

Reliability: Insulation testing ensures that LED drivers are free from defects and are reliable under normal operating conditions. This reduces the risk of failure and prolongs the lifespan of the LED driver.

Methods of Insulation Testing

There are several methods of insulation testing used for LED drivers:

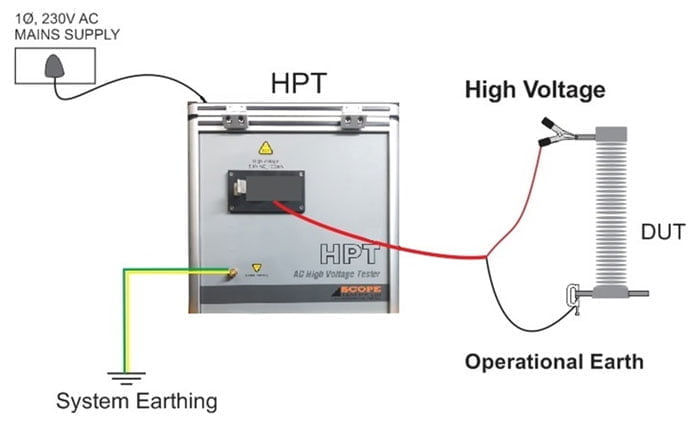

1.High Potential (Hi-Pot) Testing: This is the most common method of insulation testing for LED drivers. It involves applying a high voltage (often several times the rated voltage) to the driver’s input and output terminals while measuring the leakage current. If the leakage current is below a certain threshold, the driver is deemed to have passed the test.

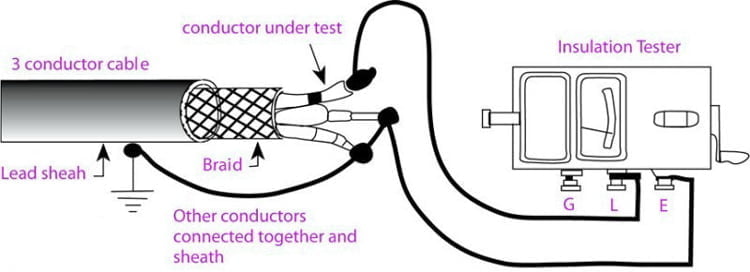

2.Insulation Resistance Testing: This method involves measuring the insulation resistance of the driver using a high-voltage ohmmeter. This test is more sensitive than Hi-Pot testing and can detect insulation resistance degradation at an early stage.

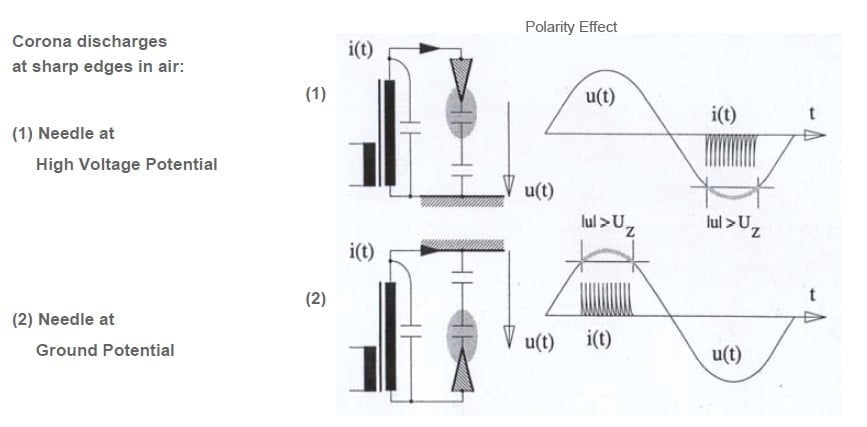

3.Partial Discharge Testing: This method involves measuring the partial discharges that occur in the insulation material when subjected to high voltage. This test is useful for detecting insulation defects and can help predict insulation failure.

4.Thermal Imaging: This method involves using a thermal imaging camera to detect any hotspots in the driver. Hotspots can indicate insulation failures or other problems that could result in driver failure.

Conclusion

Insulation testing is a critical step in ensuring the safety, compliance, and reliability of LED drivers. It helps detect insulation defects that could lead to driver failure and electrical shocks. There are several methods of insulation testing, including Hi-Pot testing, insulation resistance testing, partial discharge testing, and thermal imaging. Manufacturers of LED drivers must ensure that their drivers are tested for insulation resistance and meet relevant safety standards to ensure their safe and reliable operation.