Outdoor lighting especially street light, tunnel light are difficult and expensive to repair, so the LED drivers for those applications need not only great reliability and high protection level, but also long life so that the lights can be operating for at least 5 years. This article is showing how to make sure the LED driver is long life lasting.

Find the weakest components

LED driver is a product which is composed by hundreds of components like semiconductors, capacitors, potting materials, PCBs and magnetics etc., and electrolytic capacitor is regarded as the weakest link. So when we are calculating the life of LED driver, we should find the shortest life of all capacitors among the A, B and C.

Calculate the lifetime of electrolytic capacitor

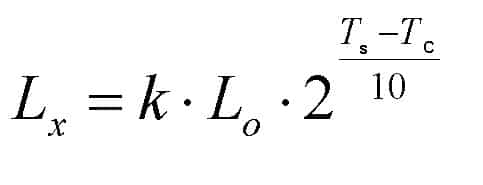

The life of electrolytic capacitor is calculated by the following equation:

k is the factor determined by capacitor’s RMS ripple current and operating voltage, it is provided as either a value or a function.

L0 is the lifetime value tested in provided in the datasheet

Ts is the rated case temperature of capacitor, and normally it is 105℃

Tc is the operating case temperature of capacitor

3 Ways to improve the lifetime

There might be other equations to calculated, but this is the most simplified one and we make it easy to illustrate the relation between the life and the key factors. Then according to the theory stated, we need to do the following key steps to do a long life driver.

Select the long life capacitor to make sure L0 is good enough.

uPowerTek is using 10,000-12,000hour@105℃ life from NCC and Rubycon. Selecting long life and high quality Japanese capacitor also helps to the extremely cold ambient operation performance because those capacitors are proved to be able to remain good performance even in the -40℃

High efficiency and good thermal conduction.

The life of capacitors increases by 2x when the temperature is decreased by 10℃. Reducing the power loss of the whole LED driver means less heat generated. And supposing the power loss is the same, then the conduction of the heat to the air or luminaire is very important. The majority of the heat is conducted through the potting material and enclosure and that is the reason why good thermal coefficient glue and thick aluminum case is used in uPowerTek LED driver.

Current ripple

The ripple current is always omitted when people are talking about life, but it does play key role in the calculation. When we check the specs of a capacitor, we see the life is 10khours @105℃ with specified ripple current. The higher ripple current, the more heat is generated by the capacitor itself. So if the ripple current is large, the internal temperature could be much higher than the case temperature of capacitor, thus the life is decreased too. uPowerTek utilizes greater capacitance to achieve the lower current ripple compared to the competitors. And that is also the reason why the uPowerTek LED driver lifetime can be 100kHours@75℃.

How to use LED drivers to have long lifetime

After understanding how to design the long life LED driver, we need to know how to use it. This is a typical lifetime vs. case temperature curve from LED driver datasheet, by which life value can be located.

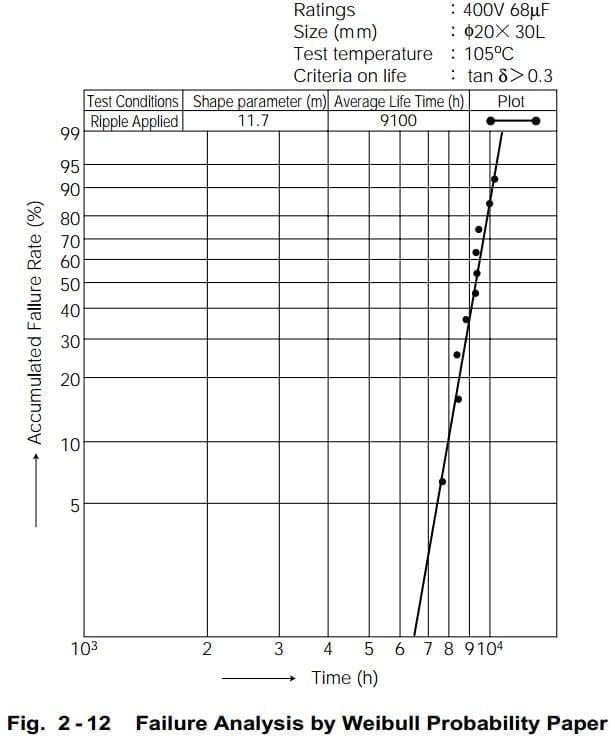

Also there is a very important definition of “end of life”, normally we regard 10% failure rate time is the “end of life”. Below is a curve regarding to failure rate vs. time from NCC capacitor handbook.

The conclusion of this paper is that designing the long life LED driver is not as easy as just doing claim. High quality components and great designs by experienced engineers are the key factors to achieve that.

You may visit this link to know more uPowerTek long lifetime LED drivers.

http://uPowerTek.com/products/