Isolated LED Driver Situation

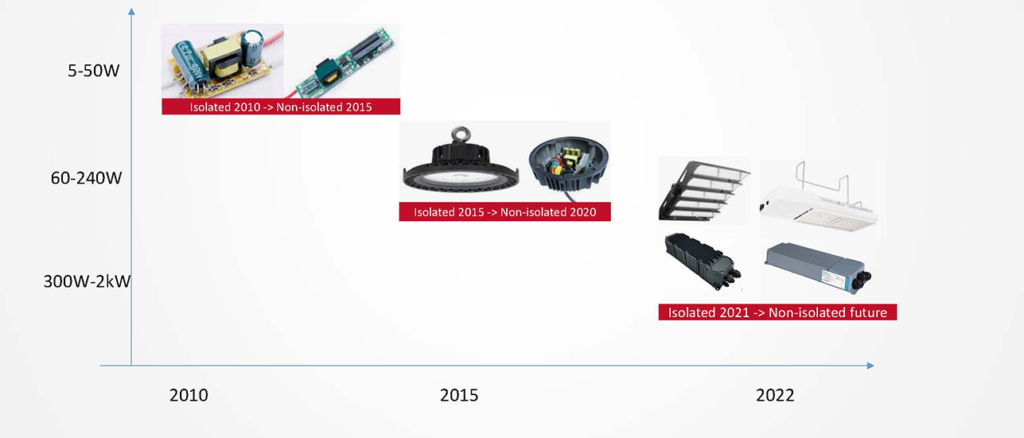

LED lights are becoming more and more mature nowadays, and the price is keeping going down. Back to 10 years ago, isolated LED drivers were applied to the LED tube. But they all changed to non-isolated LED drivers in recent years because of the lower cost. The same situation happens on high bay lights, the market share of non-isolated high bay lights gets more and more. We believe that the same situation will happen to grow lights and sports lights.

Problems without Changing

There price pressure from the market is always there, it will not disappear. Once the products get mature, competing prices will surely happen. If you don’t utilize the latest design to optimize your BOM cost, your products will not be competitive anymore. There is a high chance that your customer has to find another supplier to meet the end customer’s requirements. It’s too late then, we have to study new products and more options in advance to keep our business running healthy.

Solution – Non-isolated LED Driver

More and more grow lights and sports lights companies are evaluating the possibility of utilizing non-isolated LED drivers on their new products. With the new design, the cost can be reduced by about 20% to 30%.

Product Feature

- Supply Voltage: 90~305Vac, 380Vac for 2 hours

- 97% Efficiency Max.

- Non-isolated Design

- Output Cable with Ground Wire (Optional)

- Low Inrush Current

- 100,000Hour Life @ Tc=75℃

- 5-Year Warranty @ Tc<=75℃

- AirsetTM NFC Programmability

- +/-2% Output Current Accuracy

- Isolated 0-10V/PWM/Time/DALI2.0 Dimmable

- Glow-free Dim Off

- 12V 300mA Auxiliary Power to Power Controllers and Fans

- UL Class P, ENEC/CB/CCC SELV Output

- Global Certified Model Available

- Safety according to EN 61347-1, 61347-2-3, 61347-2-13, 62384

Non-isolated LED Driver Applications

Benefits

- Save up to 20% to 30% LED driver cost

- Compact non-isolated LED driver saves space

- The lamp gets lighter to save transport and packing cost

- The lamp gets more competitive

- Win more orders and customers with the new design.

Non-isolated LED Drivers

Square Shape

SLK Series

| Model Number | Input Voltage | Output Power | Output Current |

|---|---|---|---|

| SLK-600-C170-XYZ | 200-440Vac | 600W | 1.2-1.7A |

| SLK-600-C170-XYZ-HV0000 | 200-480Vac | 600W | 1.2-1.7A |

| SLK-700-C190-XYZ | 200-440Vac | 700W | 1.4-1.9A |

| SLK-800-C220-XYZ | 200-440Vac | 800W | 1.6-2.2A |

| SLK-800-C220-XYZ-HV0000 | 200-480Vac | 800W | 1.6-2.2A |

| SLK-1K0-C280-XYZ | 200-440Vac | 1000W | 2-2.8A |

| SLK-1K0-C280-XYZ-HV0000 | 200-480Vac | 1000W | 2-2.8A |

| SLK-1K2-C340-XYZ | 200-440Vac | 1200W | 2.4-3.4A |

| SLK-1K2-C340-XYZ-HV0000 | 200-480Vac | 1200W | 2.4-3.4A |

Slim Line

SLK Series

| Model Number | Input Voltage | Output Power | Output Current |

|---|---|---|---|

| SLK-610-C170-XYZ | 200-440Vac | 610W | 1.2-1.7A |

| SLK-610-C170-XYZ-HV0000 | 200-480Vac | 610W | 1.2-1.7A |

| SLK-810-C220-XYZ | 200-440Vac | 810W | 1.6-2.2A |

| SLK-810-C220-XYZ-HV0000 | 200-480Vac | 810W | 1.6-2.2A |

| SLK-1K1-C280-XYZ | 200-440Vac | 1000W | 2-2.8A |

| SLK-1K1-C280-XYZ-HV0000 | 200-480Vac | 1000W | 2-2.8A |

| SLK-1K1-C350-XYZ-NV0000 | 200-480Vac | 1000W | 2.8-3.5A |

| SLK-1K3-C340-XYZ | 200-440Vac | 1200W | 2.4-3.4A |

| SLK-1K3-C340-XYZ-HV0000 | 200-480Vac | 1200W | 2.4-3.4A |

BLK Series

| Model Number | Input Voltage | Output Power | Output Current |

|---|---|---|---|

| BLK-400-C200-XYZ | 120-277Vac | 400W | 1.1-2.0A |

| BLK-500-C210-XYZ | 120-277Vac | 500W | 1.4-2.1A |

| BLK-600-C210-XYZ | 120-277Vac | 600 W | 1.7-4.8A |

| BLK-610-C210-XYZ-NV0000 | 200-277Vac | 610W | 1.7-2.1A |

| BLK-610-C210-XYZ | 120-277Vac | 610W | 1.7-2.1A |

| BLK-800-C280-XYZ | 120-277Vac | 800W | 2.25-4.2A |

| BLK-810-C280-XYZ | 120-277Vac | 810W | 2.25-2.8A |

| Title | |||

|---|---|---|---|

|

SLK-1K0-C -HV0000 Rev H.pdf 1 file(s) 183 downloads |

1000W |

January 14, 2025 | |

|

SLK-1K0-C Rev H.pdf 1 file(s) 187 downloads |

1000W |

January 14, 2025 | |

|

SLK-1K1-C -HV0000 Rev G.pdf 1 file(s) 153 downloads |

1100W |

January 14, 2025 | |

|

SLK-1K1-C -NV0000 Rev G.pdf 1 file(s) 173 downloads |

1100W |

January 14, 2025 | |

|

SLK-1K1-C Rev H.pdf 1 file(s) 248 downloads |

1100W |

January 14, 2025 | |

|

SLK-1K2-C -HV0000 Rev I.pdf 1 file(s) 229 downloads |

1200W |

January 14, 2025 | |

|

SLK-1K2-C Rev H.pdf 1 file(s) 166 downloads |

1200W |

January 14, 2025 | |

|

SLK-1K3-C -HV0000 Rev G.pdf 1 file(s) 212 downloads |

1300W |

January 14, 2025 | |

|

SLK-1K3-C Rev H.pdf 1 file(s) 273 downloads |

1300W |

January 14, 2025 | |

|

SLK-600-C -HV0000 Rev G.pdf 1 file(s) 194 downloads |

600W |

January 14, 2025 | |

|

SLK-600-C Rev H.pdf 1 file(s) 252 downloads |

600W |

January 14, 2025 | |

|

SLK-610-C -HV0000 Rev G.pdf 1 file(s) 221 downloads |

610W |

January 14, 2025 | |

|

SLK-610-C Rev H.pdf 1 file(s) 176 downloads |

610W |

January 14, 2025 | |

|

SLK-800-C -HV0000 Rev G.pdf 1 file(s) 145 downloads |

800W |

January 14, 2025 | |

|

SLK-800-C Rev H.pdf 1 file(s) 147 downloads |

800W |

January 14, 2025 | |

|

SLK-810-C -HV0000 Rev G.pdf 1 file(s) 161 downloads |

810W |

January 14, 2025 | |

|

SLK-810-C Rev H.pdf 1 file(s) 193 downloads |

810W |

January 14, 2025 | |

|

BLK-400-C Rev H.pdf 1 file(s) 185 downloads |

400W |

January 14, 2025 | |

|

BLK-500-C Rev I.pdf 1 file(s) 194 downloads |

500W |

January 14, 2025 | |

|

BLK-600-C Rev D.pdf 1 file(s) 176 downloads |

600W |

January 14, 2025 | |

|

BLK-610-C -NV0000 Rev G.pdf 1 file(s) 212 downloads |

610W |

January 14, 2025 | |

|

BLK-610-C Rev I.pdf 1 file(s) 222 downloads |

610W |

January 14, 2025 | |

|

BLK-800-C Rev C.pdf 1 file(s) 155 downloads |

800W |

January 14, 2025 | |

|

BLK-810-C Rev H.pdf 1 file(s) 219 downloads |

810W |

January 14, 2025 |

FAQ

What should be paid attention to when designing my non-isolated lamps?

It is not easy to find a right non-isolated driver for high-power design, the following has to be considered carefully:

- Efficiency and thermal. Non-isolated drivers have the advantage of efficiency compared with conventional isolated drivers. But it does not mean efficiency is not important. Better efficiency means lower power loss and less heat generation thus the LED driver can have a longer life and higher reliability with a better thermal situation. Checking the case temperature at Tc point is mandatory for a good luminaire design.

- Dimming performance. Using a lower-cost driver does not mean we have to sacrifice performance. Smooth dimming with either 0-10V or DALI or DMX control compatibility is important for stadium lights, especially the fast dimming response.

- Find the right input voltage range for different countries.

- Try to use the high LED voltage to achieve the best efficiency.

- Utilize the LED board with higher insulation. 3kV insulation voltage is suggested.

- Do adequate insulation for the whole luminaire to make sure that all the points that can be touched by the human body are safe and able to pass the insulation test.

How do you solve the glow issue when dimming off?

- Do NOT use the way of lowering output voltage to dim off because different LED behaves differently and we don’t know by how much voltage, the LED may conduct. So the eliminate the possibility, we need to totally shut down the LED driver rather than just lowering down the output voltage. Also, there is another benefit that the standby power is much lower because the driver is in “sleep mode”. But the other result is that the cost of the driver is higher by adding such kind of circuitry inside the driver.

- To avoid the common mode leakage current through the parasitic capacitors, we have two ways, either disconnect the earth or disconnect the input/output during the dim-off status. Obviously, we are not allowed to disconnect the earth by safety standards with AC line connected. So the only way to have to do is to disconnect the input or output to LED by an internal relay. Also, the drawback is the higher cost.

Making sure of the darkness for cannabis and vegetable grow is so important that the LED driver manufacturers like uPowerTek is paying great efforts to the designs to avoid “glow” in off status. For the luminaire designers, you have to make sure that the luminaire is fully tested in the dark room before finalizing the product. Please feel free to let us know if you have any questions.

Get in touch now!

Meet Our Team

We have a professional team to support you, you will get a reply within 24 hours, tell us more about your projects, let’s see what we can do for you.