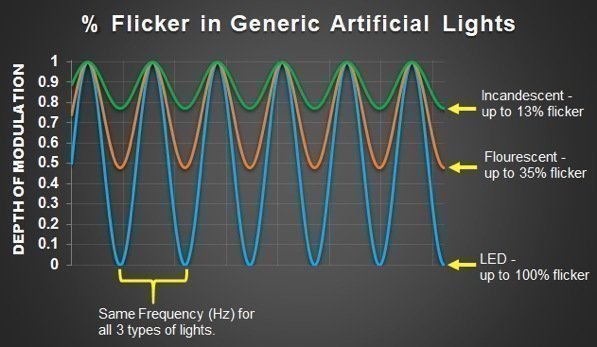

It is a trend in the lighting industry to replace traditional incandescent and fluorescent lamps with more efficient and longer-life LEDs. However, since it is directly connected to the AC line, like the traditional pioneers, there may be a risk of 100Hz or 120Hz flicker due to the drive current ripple at the output of the power supply, although most of the time this may make consumers feel uncomfortable with humans. The eyes cannot notice them. LED and lamp manufacturers are eager to solve this problem, they turn to the LED driver manufacturer because, in the end, the LED driver determines whether or not to flicker. This article investigates the causes of flicker, describes how LED flickers occur, and explains how engineers can trade-off between different solutions to solve the problem. Finally, it provides a cost-effective and flexible way to achieve flicker-free LED lighting using ripple suppressors.

LED lamps will replace most other lamps, such as incandescent lamps and fluorescent lamps in the next few years. This is a well-known trend that LED is a new generation of light source. People not only look forward to higher light efficiency, but also look forward to a better light environment.

Most LED lights are directly connected to the AC power grid. Depending on the region, there are 50Hz or 60Hz, and the frequency after AC rectification is very low even 100Hz or 120Hz, which may cause stroboscopic flicker and cause some anxiety. If the LED driver is designed to use a single stage PFC design, you can even get sick.

Now lamp manufacturers are realizing and trying to solve this problem, especially indoors. So they turned to professional LED driver manufacturers for help and solutions. This article will explain how flicker is affected by LED ripple current, and explain the many ways to solve the problem through the correct LED driver design, especially a unique device called a ripple suppressor, which allows lamp manufacturers to They are already employed to minimize the ripple current without changing the current LED driver.

The Impact of Flicker

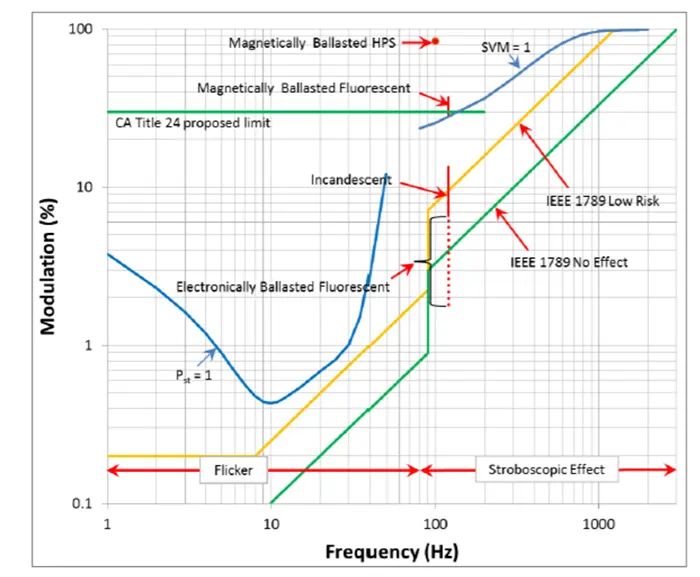

Light flicker frequencies in the range of 3 to 70 Hz are easily perceivable by humans, which can make them very uncomfortable. Even repetitive flashes and static repetitive geometric patterns may induce epileptic seizures in these people, and the incidence is about 0.025%. And this kind of flicker can be easily solved by the LED driver. If we see this frequency in the output current ripple waveform, we usually think that the LED driver is unstable. People are beginning to pay more attention to the fact that long-term exposure to higher frequency flicker (in the range of 70-160 Hz) can also cause discomfort, headaches and visual disturbances. For LED drivers, since the grid frequency in most parts of the world is 50Hz or 60Hz, the most common ones are 100Hz and 120Hz flicker. So this article mainly discusses how to deal with 100Hz or 120Hz flicker. In fact, the impact of 100Hz or 120Hz flicker on human health is not only a function of frequency but also related to physiological and physiological factors.

Some researchers even claim that the retina can perceive flicker up to 200 Hz, but tests have shown that above 160 Hz, the impact of flicker on health is negligible.

Defining the Flicker

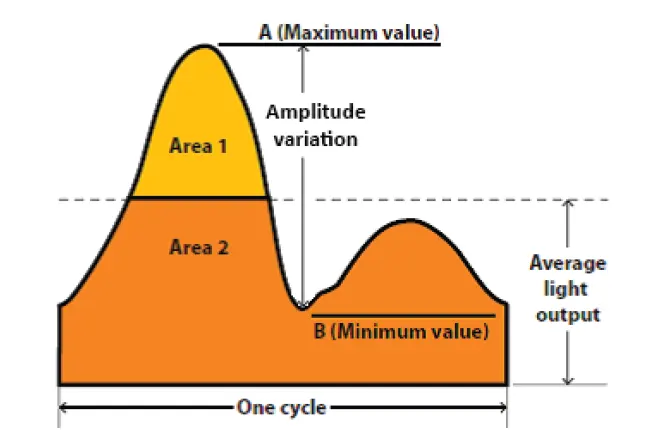

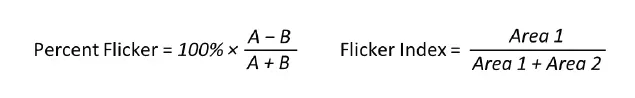

IESNA (the Illuminating Engineering Society of North America) released the definition of “percent flicker” and “flicker index” in the ninth edition of The IESNA Lighting Handbook. Figure 1 shows how the metrics are defined.

Percent flicker is a relative measure of the cyclic variation in output of a light source (i.e., percent modulation). This is also sometimes referred to as the “modulation index.”

Flicker index is a “reliable relative measure of the cyclic variation in output of various sources at a given power frequency. It takes into account the waveform of the light output as well as its amplitude,” according to the handbook. The flicker index assumes values from 0 to 1.0, with 0 for steady light output. Higher values indicate an increased possibility of noticeable lamp flicker, as well as stroboscopic effect.

As noted above, in addition to the frequency, the flicker index has a significant effect on how the light makes people feel. Higher flicker index means the more sensitivity to the human eye and the poorer comfort level. Table below shows the typical flicker index of different lights engines.

| Max | Min | Ave | Flicker% | Flicker Inde | |

|---|---|---|---|---|---|

| Incandescent | 12.180 | 10.745 | 11.460 | 6.2594 | 0.0194 |

| 100 W MH | 9.1472 | 3.2066 | 6.5147 | 48.088 | 0.1398 |

| T12 Magnetic | 9.6281 | 4.6256 | 7.1565 | 35.096 | 0.0897 |

| T5HO Elec | 10.52 | 9.960 | 10.20 | 2.734 | 0.0036 |

| LED at DC | 43.4 | 41.0 | 42.2 | 2.84 | 0.0037 |

| LED w/ Flicker | 15.996 | 0.0555 | 6.3026 | 99.309 | 0.4498 |

The IEEE Standards Working Group IEEE PAR1789 “Recommended Practices for Adjusting Current in High Brightness LEDs to Reduce the Health Risks of Audiences” has been established to provide the lighting industry, ANSI/NEMA, IEC, EnergyStar and other standards organizations with recommendations on emerging concerns LED The light flashes. This article introduces the flicker-related health issues to LED lighting power electronics designers, proves that the existing technology in LED lighting sometimes provides flicker at a frequency that may cause the human body’s biological response, and discusses attempts to mitigate unintentional biological effects. Some methods to consider when LED lighting. This paper represents work in progress in IEEE PAR1789, which is essential for the design of safe LED lamp drivers.

And according to the paper https://fhi.nl/app/uploads/sites/32/2017/09/Te-Lintelo-Systems-LED-Flicker-%E2%80%93-where-we-are-with-test-methods-and-standards.pdf

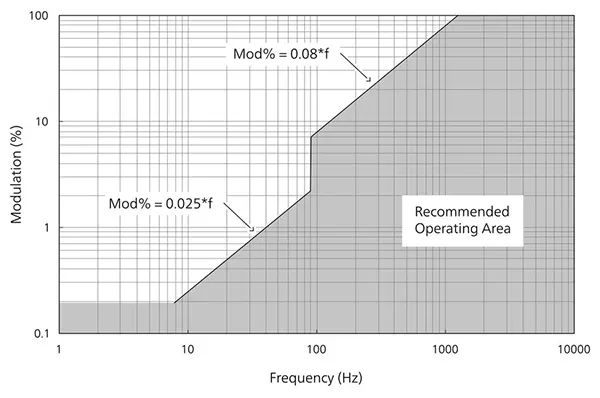

We have the following curve.

Solid state light source feature

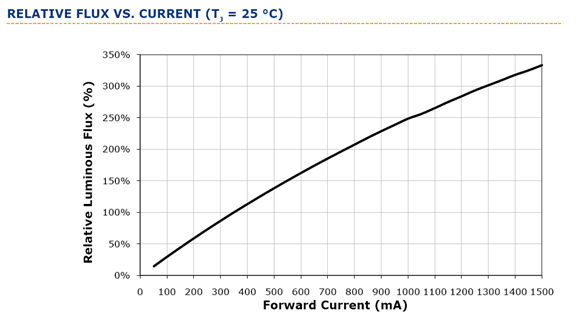

The LED light output is almost linear with the driving current as the figure below shows, so it is quite obvious that the critical reason of LED light flicker is caused by the driving current, which is originally provided by the LED driver. So the basic solution is to make sure LED driver output current is stable without large ripple.

Solutions of LED Drivers for Indoor Applications

When we are talking about the 100Hz or 120Hz flicker, in most of the cases, it is about the indoor applications. There are quite a few LED driver schemes for indoor to provide a constant current like simple resistor, linear semiconductor regulation, and switching PWM regulation after the AC rectification, but those schemes are beyond the discussion in this paper because they are not able to provide qualified power factor (PF) which is normally required to be over 0.9. More and more countries and standard associations like Energy Star and DLC (Design Lights Consortium) require the lights to have over 0.9 PF value, and it can be predicted the lamps and luminaries without 0.9 PF will be phased out soon. Here some qualified methods to achieve the PF are discussed and compared. Also a new kind of scheme to lower the existing large ripple from single stage LED driver is introduced as below.

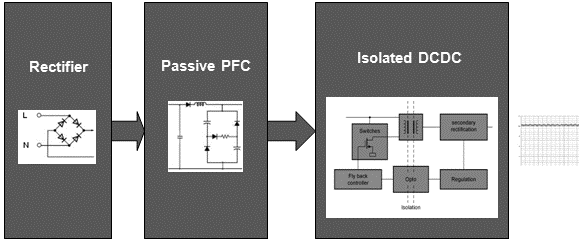

1.Passive (Valley Fill) PFC plus switching DCDC

This structure is widely used in low-cost offline adapters and chargers. Thanks to the valley-filling circuit and large-capacity capacitors, the current ripple of this solution is small and easy to control. The disadvantage of this scheme is that the PF is poor, it cannot pass the EN61000-3-2 (harmonic current emission test) Class C standard, and it is not suitable for higher powers above 20W. In addition, this solution is not suitable for realizing wide input voltages of 100Vac-240Vac.

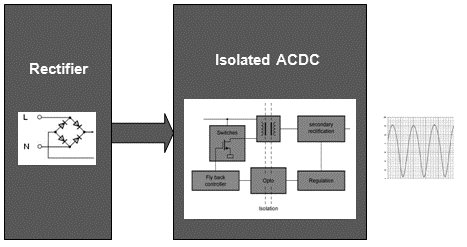

2.Single Stage Active PFC

This is a widely adopted topology for wide input range LED drivers. It has good product efficiency and PF value and a wide load range. The disadvantage is that high current ripple can cause visible or invisible 100Hz/120Hz flicker. A good design can reduce the current ripple to a relatively low value, but the ripple is usually still higher than the previous scheme. An interesting feature of this scheme is that the ripple is greatly affected by the V-I characteristics of different LED loads. So in order to completely control the ripple of this scheme, LED driver manufacturers are looking for better solutions.

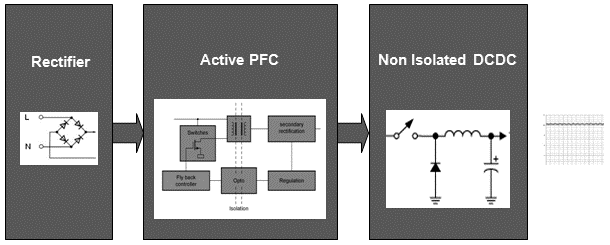

3.Active PFC plus switching DCDC

In order to solve the problem of single-stage PFC, an additional DCDC needs to be added to the drive, which increases the cost by 15-20%. This circuit greatly reduces the output current ripple, making the output almost ideal DC, but it will lose 2-3% efficiency. And this structure can cover most of the power levels for indoor applications.

In summary

With the development of the LED lighting industry, the characteristics of high efficiency and long life can no longer satisfy the market. People are looking for a better light environment, especially a healthy light environment. For certain places such as offices and living rooms, no flicker is more important.

There are many ways to generate a good low-ripple DC current to drive the LED, and each method has its advantages and disadvantages. The main advantage of the ripple suppressor is that it provides a very simple and flexible method that can reduce the flicker of our existing designs by increasing a reasonable cost.

| Design Complexity | Cost | Efficiency | AC Input Range | Ripple Current | |

|---|---|---|---|---|---|

| Passive PFC + DCDC | Low | Low | High | Narrow | Medium |

| Active PFC | Low | Low | Medium | Wide | Large |

| Active PFC + DCDC | High | High | 2-3% lower | Wide | Small |

The low-ripple design of LEDs will still be a research goal for a long time in the future, and professional LED driver manufacturers like uPowerTek will continue to find better solutions for the market.

Still have questions? Get in touch now!